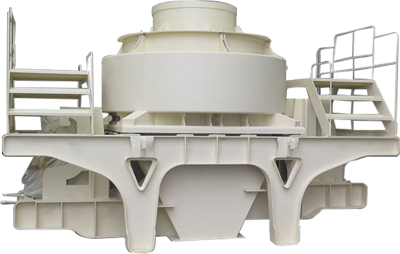

Dolomite sand making machine

Feed particle size35-60mm.

Processing capacity12-360t/h.

Applicable materialCement, refractory materials, metallurgy, roads, railways, water conservancy, airports, construction and other industries..

Sell Hot: South Africa, Nigeria, Kenya,Mexico, Uzbekistan, Chile, Tanzania, Peru, Brunei, Brazil, Iran, Philippines, Malaysia, Vietnam, Pakistan, India, Russia, Venezuela, USA, etc.

free delivery this machine related parts!

Dolomite is a carbonate mineral, belonging to the third-party crystal system, which is rhombohedral, often associated with gypsum, anhydrite, stone salt and so on. China's dolomite resources are very rich, widely used in refractory materials, cement, glass, agriculture, construction and other fields. The sand making of dolomite is mainly completed by the dolomite sand making machine. The dolomite sand making machine is mainly composed of the feeding hopper, the crushing cavity, the impeller, the main shaft assembly and the transmission device, and is a widely used dolomite efficient. Processing Equipment. The dolomite material processed by sand has higher economic value and wider application fields, which greatly improves the application value of dolomite in various fields.

Parameters

Dolomite sand making machine performance advantage

Unique technology

The hammer head of the dolomite sand making machine is made of high-manganese steel with good wear resistance, which can effectively guarantee its impact resistance and reduce the wear of the equipment in the production process.

No pollution

The dolomite sand making machine adopts advanced water-sealing components with reasonable design and compact structure, which can effectively prevent the entry of dust and reduce the environmental pollution caused by production.

Heavy load

The dolomite sanding machine features an advanced bearing and spindle design that features heavy duty and high speed rotation.

No wear on the fuselage

The material layer formed by the material can protect the equipment and avoid the wear of the fuselage.

Principle

working principle

After the naturally mined dolomite material enters the sand making machine, it is divided into two parts through the distributor, and a part enters the high-speed rotating impeller, which is instantaneously accelerated, and its acceleration can reach hundreds of times of gravity acceleration, and then the impeller is from three. The uniformly distributed flow channels are ejected out, and the other parts are scattered and crushed by the surrounding materials to achieve preliminary crushing. Then the two parts of the materials impact together on the material lining in the vortex cavity, and are rebounded by the material lining. Impact on the top of the vortex chamber, then change to the ground to form a continuous material curtain, which is discharged through the discharge port. The equipment runs stably throughout the production process and there is no dust pollution.

Send Enquiry

write down your requirement and contact details in the following form to get the latest price of this product within one day!

Hot Product

Pursuit of excellence, innovation is not limited!