Fine sand recycling machine

Feed particle size≤10mm.

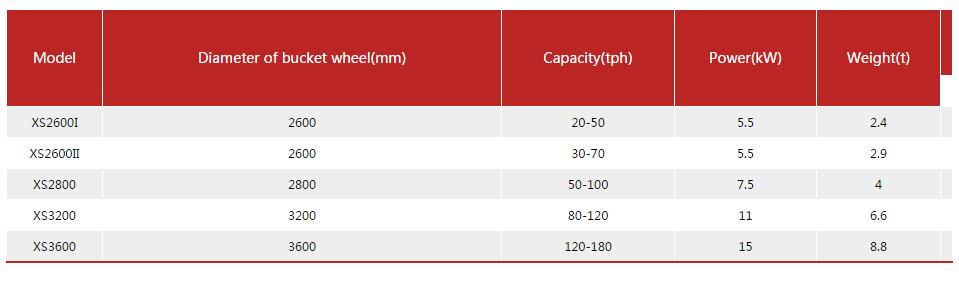

Processing capacity20-180tph.

Applicable materialPebble, basalt, granite, limestone, iron ore, river stone.

Sell Hot: South Africa, Nigeria, Kenya,Mexico, Uzbekistan, Chile, Tanzania, Peru, Brunei, Brazil, Iran, Philippines, Malaysia, Vietnam, Pakistan, India, Russia, Venezuela, USA, etc.

free delivery this machine related parts!

The fine sand recycling machine is mainly used in the section after the sand washing process in the sand production line. The tailings slurry after washing the sand can be absorbed into the device through the slurry pump for dehydration, de-sludge, screening and recovery, and finally obtained. Fine sand for industrial use. According to the design structure, there are currently three kinds of fine sand recycling integrated machines in the industry, which are wheel washing and recycling machine, spiral sand washing and recycling machine and mobile sand recycling machine. All three equipments can be used in various environments. The next operation can be carried out in a single machine, or combined with other equipment for multi-machine operation, which can better reduce the production cost of users and increase the user's revenue.

Multiple functions, efficient and convenient

The fine sand recycling machine has multiple functions such as sand washing, sieving, dewatering and recycling. The sand and gravel treatment is in one step, the whole machine has strong stability, high efficiency, high degree of automation and higher application value.

Outstanding work, fewer failures

The fine sand recycling machine is cleaner than the traditional sand washing machine, the fine sand loss rate is lower, the working effect is immediate, the whole machine equipment is simple in structure and easy to operate, because it is not engaged in impact work with too much strength, the equipment is faulty. The rate is very low.

Energy saving, performance and environmental protection

The fine sand recycling machine can be configured according to different production requirements and working environment, to improve the efficiency of the operation and reduce the energy consumption, and the slurry recovered from the fine sand is less sedimented in the sedimentation tank, and the environment is protected. It is also conducive to the recycling of water resources.

Parameters

Principle

Fine sand recycling machine structure and working principle

The complete equipment of the fine sand recycling machine consists of vibration motor, sediment separator, dewatering screen, vacuum high pressure pump, high pressure separator, high return water tank and cleaning tank.

Working principle: the slurry containing sand, water, mud powder, stone powder and other mixture is sent to the cleaning tank, and the sand is separated from other impurities by the sediment separator. After the separated fine sand slurry enters the lower dewatering sieve for dehydration treatment, The waste water overflowing from the cleaning tank (including a small amount of qualified materials that have not been picked up by the sand washing wheel, waste water, impurities) enters the back-end pumping tank, is pumped into the high-pressure separator through the vacuum high-pressure pump, and is finely concentrated by centrifugation. The sediment mouth is discharged into the upper layer of the dewatering sieve, and the waste water, mud, dust, impurities, etc. in the cleaning tank are discharged through the overflow port of the high-pressure separator, discharged into the high-level return water tank, and discharged, the upper layer is discharged into the finished material coarse sand, and the lower layer is discharged from the finished product fine sand. , or mixed with coarse and fine sand.

Send Enquiry

write down your requirement and contact details in the following form to get the latest price of this product within one day!

Hot Product

Pursuit of excellence, innovation is not limited!