Limestone crush plant

What can help you, fill out the form below and submit, we will get back to you as soon as possible.

The main mineral component of limestone is calcite. It has rare crystal structure and mineral particles and its surface is smooth and granular. Colors are black, gray, white, yellow and brown. Limestone containing seawater formation lime, hence the name o

The main component of limestone is calcium carbonate. Lime and limestone are used in large quantities as building materials and are important raw materials for many industries. Limestone can be directly processed into stone and fired into quicklime. The lime absorbs moisture or adds water to become slaked lime. The slaked lime is also called slaked lime. The slaked lime is blended into lime slurry, lime paste, lime mortar, etc., and is used as a coating material and a tile adhesive. Due to the medium hardness of limestone, it is generally broken by a heavy hammer counter crusher.A complete limestone crushing production line consists of feeding system, crushing system and screening conveying system. The main equipments include vibrating feeder, heavy hammer counter crusher and vibrating screen equipment. The specific limestone production line equipment configuration is mainly based on customer pairs. The specifications, production requirements and uses of the finished materials are determined, and different types of equipment are selected according to the customer's production site, and strive to provide customers with a reasonable production line.

Vibrating feeder:

The vibrating feeder is commonly known as the feeder. In the limestone production line, the raw materials can be uniformly and continuously sent to the heavy hammer counter crusher, and the materials can be roughly sieved to screen out the waste soil without use value. It is a feeding equipment with stable economic performance, high efficiency and easy operation. Heavy hammer crusher:

Heavy hammer crusher:

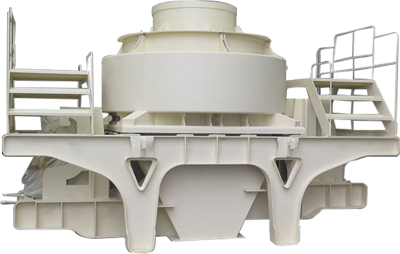

Broken is the link of the whole limestone production line. Zhongyin Dingli Heavy Hammer Counter-Crusher truly realizes a broken forming, strong crushing capacity, and the output can reach 3,000 tons in one hour, which is suitable for large limestone crushed stone production line. The equipment has the advantages of large crushing ratio, strong applicability, adjustable and uniform particle size, low energy consumption, and simple operation and maintenance. If the customer requires too much production or the material size is too large, multiple crushers can be configured to meet the demand. Vibrating screen:

Vibrating screen:

The vibrating screen plays a role in classifying the material in the limestone production line, and divides the crushed finished sand and stone into different finished material piles. The commonly used circular vibrating screen has many layers, new and high efficiency, and the equipment structure is reliable and exciting. It can be widely used in product grading of energy and chemical industries.

Vibrating feeder:

The vibrating feeder is commonly known as the feeder. In the limestone production line, the raw materials can be uniformly and continuously sent to the heavy hammer counter crusher, and the materials can be roughly sieved to screen out the waste soil without use value. It is a feeding equipment with stable economic performance, high efficiency and easy operation.

Broken is the link of the whole limestone production line. Zhongyin Dingli Heavy Hammer Counter-Crusher truly realizes a broken forming, strong crushing capacity, and the output can reach 3,000 tons in one hour, which is suitable for large limestone crushed stone production line. The equipment has the advantages of large crushing ratio, strong applicability, adjustable and uniform particle size, low energy consumption, and simple operation and maintenance. If the customer requires too much production or the material size is too large, multiple crushers can be configured to meet the demand.

The vibrating screen plays a role in classifying the material in the limestone production line, and divides the crushed finished sand and stone into different finished material piles. The commonly used circular vibrating screen has many layers, new and high efficiency, and the equipment structure is reliable and exciting. It can be widely used in product grading of energy and chemical industries.

Limestone crush plant

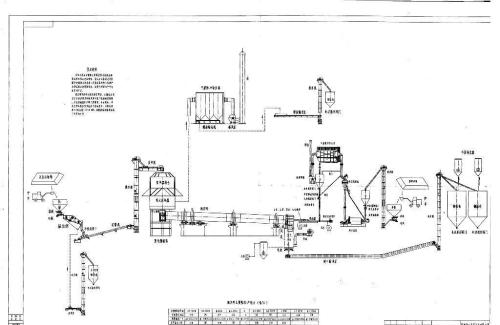

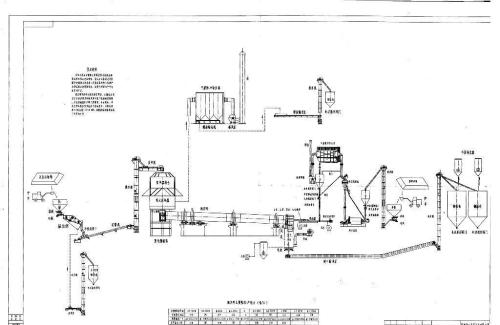

The limestone is evenly transported by the vibrating feeder to the limestone crusher. According to the requirements of the discharge size, the crusher can be configured in three modes: coarse crushing, medium crushing and fine crushing. After the limestone is crushed, it is carried out by the vibrating screen and the belt conveyor. Screening. If the particle size requirement is too high, a crusher can be equipped for secondary crushing until the finished product can fully meet the customer's requirements.

The limestone is evenly transported by the vibrating feeder to the limestone crusher. According to the requirements of the discharge size, the crusher can be configured in three modes: coarse crushing, medium crushing and fine crushing. After the limestone is crushed, it is carried out by the vibrating screen and the belt conveyor. Screening. If the particle size requirement is too high, a crusher can be equipped for secondary crushing until the finished product can fully meet the customer's requirements.

Relate:Single spiral sand washing machine,

Sand making machine,

Sand production line,

HVI sand making machine,

Bucket Wheel Sand Washer,

GZD Vibrating Feeder,

Mobile impact crusher,

VSI sand making machine,

Vibrating feeder,

Stone powder sand washing machine,

Mobile Screener,

Trommel Screen,

Vertical Shaft Impact Crusher,

Mobile sand making machine,

Sand washing & recycling machine,

Heavy hammer crusher,

Spiral sand washer,

Belt Conveyor,

Double spiral sand washer,

Fine sand recycling machine,

Mobile screening plant,

mobile cone crusher,

Hammer Crusher,

Conveyor belt,

Dolomite sand making machine,

River stone sand making machine,

Mobile crushing station,

Jaw Crusher,

Circular Vibrating Screen,

limestone Mobile screener,

Symons Cone Crusher,

Hydraulic Cone Crusher,

Basalt sand making machine,

Granite production line,

Impact Crusher,

Send Enquiry

write down your requirement and contact details in the following form to get the latest price of this product within one day!

Hot Product

Pursuit of excellence, innovation is not limited!